Week 12 - 3D printing

- imanghazzali

- Jul 19, 2021

- 2 min read

Digital fabrication

Digital fabrication is a type of manufacturing process where the machine used is controlled by a computer.

Why digital fabrication? Digital fabrication is fast becoming an important enabling technology in many chemical engineering fields.

Such as addictive technology in the oil & gas industry.

Also, it is good for prototyping and good for end-use parts.

Additive Manufacturing (AM)

It is an appropriate name to describe the technologies that build 3D objects by adding layer upon layer of material.

It can use any material from plastic to concrete.

Also, it is limitless.

Advantages of Additive Manufacturing (AM)

Manufacturing & Assembly in one part - can combine assemblies into single parts, which can reduce overall product cost in unique situations.

Cost of 3D printers - are affordable and common materials.

Prototyping costs much less - Make the necessary design changes, print a new part, and have near verification that your updated design fits the requirements.

Application of Additive Manufacturing (AM)

AM has gone from prototyping and tooling to manufacturing in industrial sectors such as architectural, medical, dental &, etc.

3D printing technology (FDM, SLA, SLS)

3D printing material

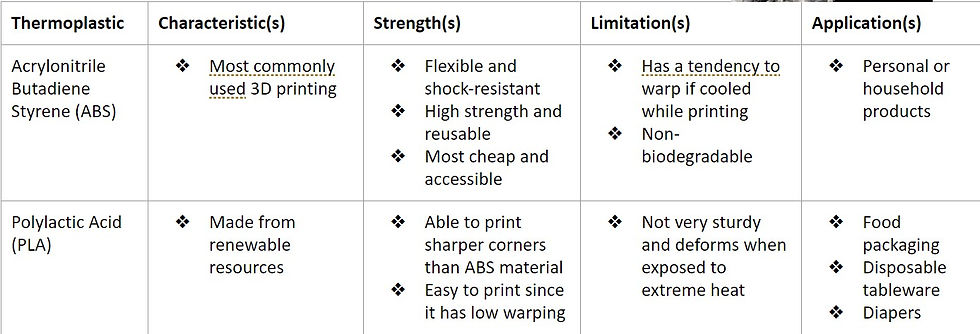

Suitable thermoplastics for FDM 3D printing

3D printing slicer settings

Layer Height

Layer height is a very influential factor in slicers and refers to the height of each layer of your print.

The smaller the layer height, the more layers will be required in the overall print.

Print speed

A faster print will affect the quality of the bridging negatively

The printer will not have enough time to connect 2 layers together

Therefore the print speed should be slower.

Part Orientation

Quality, Strength, and surface finish will be affected.

Print incorrectly affecting the quality of the product and surface finish.

Incorrectly bridge parts together affecting the structural integrity and strength of the item

Supports

Increases material costs, printing durations.

Needs to be removed before the model is ready.

Risk of damaging the model.

Needed when there are overhangs and bridges that are not supported by anything below.

Cooling fans

Infill

Internal filling of 3D printed parts.

In a slicer, infill can be controlled using infill density, set as a percentage, and infill pattern, which is the infill structure or form.

A more robust infill will increase the strength of the printed parts.

For strong parts select choose cubic patterns for flexible parts choose a concentric pattern.

Shell thickness

The parameters of the print

Infills are the “Insides” Shells are the “outside” of the print

Select higher shell thickness for a stronger print

Comments